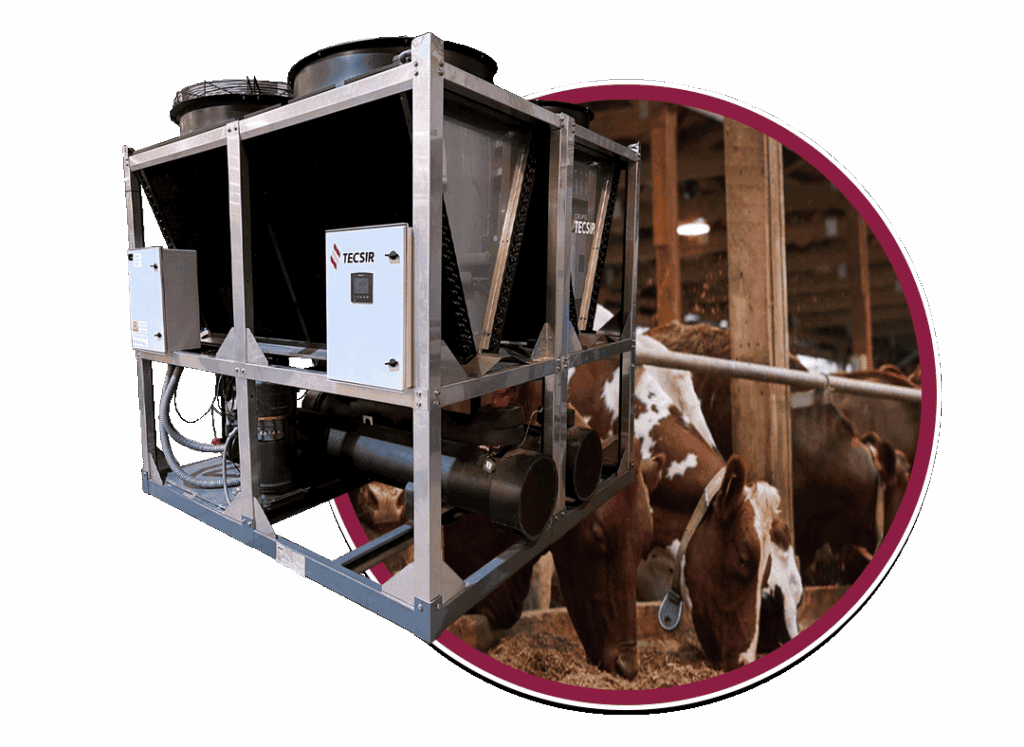

Chillers for the Dairy Industry: Advanced Refrigeration for the Future of Your Dairy Products

The dairy industry faces a constant challenge: maintaining the quality and freshness of its products. From the farm to the supermarket, the dairy cold chain is a crucial link. A failure in it not only affects product quality but also directly impacts company profitability. At TECSIR Group, we understand the importance of efficient industrial refrigeration and we present the future of refrigeration for milk and dairy products.

The Impact of the Cold Chain on Dairy Quality

Milk and milk products are highly perishable. Maintaining a constant temperature between 0-4°C (32-36°F) is vital to preserve their freshness, flavor, and safety.

Studies show that an increase in milk storage temperature of just 2°C (35°F) can reduce its shelf life by half. Critical points where disruptions in the dairy cold chain often occur are during loading, unloading, and storage at retail locations. These disruptions not only result in significant losses but also impact long-term investment in efficient dairy refrigeration systems.

Refrigeration in the Dairy Industry: A Global Challenge

Globally, large volumes of dairy products are wasted annually due to the lack of adequate cold storage and distribution systems. The Food and Agriculture Organization of the United Nations (FAO) estimates that one-third of the food produced globally for human consumption is lost or wasted. Implementing industrial chillers and efficient cold chain logistics, especially in developing countries, could transform these primary products into secondary products and resell them to local and international consumers, driving industry growth.

La “Cadena Fría”: Pilar del Éxito en Productos Refrigerados

Los alimentos refrigerados son uno de los sectores de mayor crecimiento en la industria alimentaria. Su éxito continuo depende de una gestión impecable de la “Cadena Fría”, que abarca desde la producción hasta la venta al por menor. En el sector lácteo, esto significa que desde que la leche sale de la ubre, debe ser mantenida a una temperatura óptima de 4 °C para asegurar su máxima calidad. La implementación de equipos de refrigeración industrial adecuados y un control riguroso son cruciales para preservar la seguridad y calidad de los alimentos refrigerados y cumplir con las directivas legislativas y los “códigos de práctica” de la industria.

The Future of Dairy Refrigeration: Control Engineering and Smart Chillers

Control engineering and remote monitoring systems are key allies for the future of the dairy industry. At Grupo TECSIR, we are committed to solutions that integrate bulk milk chiller management with IoT (Internet of Things) technology. This enables:

- Detailed Reporting: For accurate performance analysis.

- Waste reduction: Minimizing product losses.

- Enhanced monitoring: Real-time temperature control.

- Optimized efficiency: Maximizes the performance of dairy chillers.

Modern, microcontroller-based solutions address advanced automation and control requirements. Security is paramount: digital locking systems and tamper-evident management reduce potential cyberattacks, ensuring milk quality. Furthermore, cloud platforms enable preventive diagnostics, preventing failures and misuse.

At TECSIR Group, we offer high-efficiency chillers and industrial refrigeration solutions specifically designed for the dairy industry. Our equipment will help you maintain quality, reduce operating costs, and ensure the safety of your products.